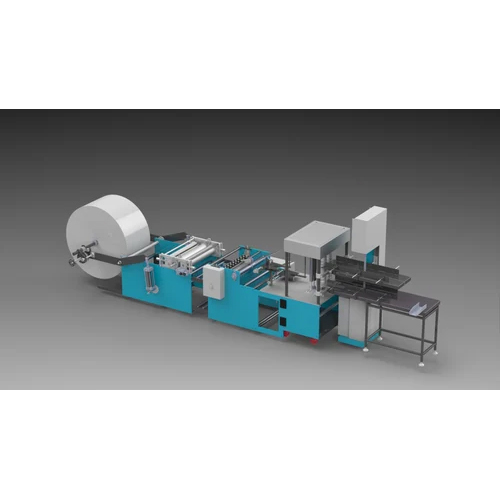

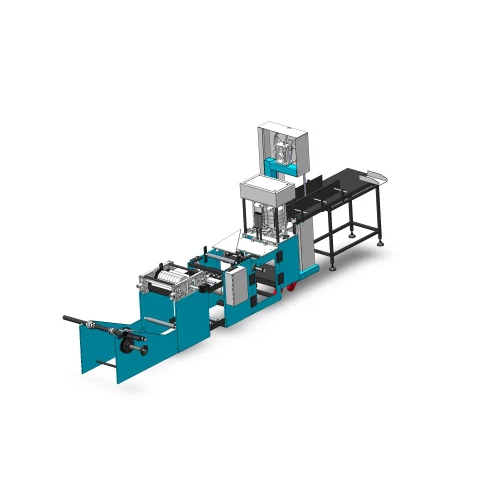

Industrial Tissue Paper Making Machine

Price 480000.00 INR/ Unit

Industrial Tissue Paper Making Machine Specification

- Grade

- Automatic

- Type

- Paper Cutting Machine

- Material

- Paper

- Capacity

- 32 Kg/hr

- Computerized

- Yes

- Control System

- PLC Control

- Cutting Speed

- 375 m/m

- Cutting Size

- 20-40

- Voltage

- 440 Volt (v)

- Power

- 5-10 Watt (w)

- Weight (kg)

- 2 Metric Ton

- Dimension (L*W*H)

- 14 * 4 * 5 Foot (ft)

- Color

- White

- Warranty

- 1 year

Industrial Tissue Paper Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 8 Units Per Month

- Delivery Time

- 30 Days

- Packaging Details

- Standard Practice

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO

About Industrial Tissue Paper Making Machine

Fully automatic multi size tissue napkin making machineBeing a prominent organization, we are providing our esteemed clients with an innovative assortment of fully automatic multi size tissue napkin making machine. Energy efficient, easy installation, long service life and easy to operate are qualities of offered paper making machine. This machine is used for manufacturing of tissue paper. This machine is used to perforate and cut the raw paper into various sizes according to the requests. In addition to this, fully automatic multi size tissue napkin making machine is available in different specifications at competitive prices. This machine has 2.2 kW Power and 440 V Voltage.

Advanced Automatic Operation

The tissue paper making machine leverages PLC control for seamless, computerized operations. With its automatic grade, it minimizes manual intervention and ensures consistent quality, optimizing output at an impressive capacity of 32 kg/hr.

Precision and Versatility in Paper Cutting

This machine is capable of cutting paper from 20 to 40 cm, with a rapid 375 meters per minute cutting speed. Its state-of-the-art design allows for adaptation to various production requirements, making it suitable for both small and large-scale factories.

Robust and Efficient Design

Crafted from durable materials and weighing 2 metric tons, the equipment stands out for stability and extended operational life. It is engineered to deliver high performance within a compact footprint, supported by a comprehensive 1-year warranty for peace of mind.

FAQs of Industrial Tissue Paper Making Machine:

Q: How does the PLC control system enhance the tissue paper making process?

A: The PLC (Programmable Logic Controller) system automates the entire production process, ensuring precise control of cutting speed and size. It allows seamless adjustment and minimizes errors, enhancing productivity and consistency.Q: What are the primary usage scenarios for this tissue paper making machine?

A: This machine is ideal for industrial tissue paper manufacturers seeking high volume, precision-cutting, and automated operations. Its robust capacity and computerized features suit manufacturers, exporters, and suppliers nationwide.Q: When is maintenance required for optimal machine performance?

A: Routine maintenance, such as checking mechanical parts and ensuring the PLC system is functioning correctly, is recommended every 3-6 months. Professional servicing and using genuine parts are advised to uphold the 1-year warranty.Q: Where can this machine be installed and operated effectively?

A: The machines compact dimensions (14 x 4 x 5 ft) make it suitable for installation in industrial manufacturing facilities. It operates best in locations with a stable 440 V power supply and proper ventilation.Q: What is the process of converting paper material into finished tissue products?

A: The machine feeds paper material and automatically cuts it into specified sizes (20-40 cm) at high speeds using computerized settings. The finished tissue papers are then collected, ready for packaging and distribution.Q: What are the key benefits of using this automatic tissue paper making machine?

A: Users enjoy high production efficiency, minimal manual labor, precise cutting, and reduced downtime. The reliable PLC control and robust construction ensure consistent quality and long-term usability, backed by a 1-year warranty.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tissue Paper Making Machine Category

Automatic Tissue Paper Making Machine

Price 480000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Frequency Speed Control

Grade : Automatic

Material : MS, SS

Computerized : No

Printed Tissue Paper Making Machine

Price 820000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Grade : Automatic

Material : MS

Computerized : No

All Size Tissue Paper Making Machine

Price 1100000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Grade : Automatic

Material : MS

Computerized : No

Electric Tissue Paper Making Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Grade : Automatic

Material : SS

Computerized : No

GST : 24CNQPP5534B1ZY

|

|

RAJSHREE INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry