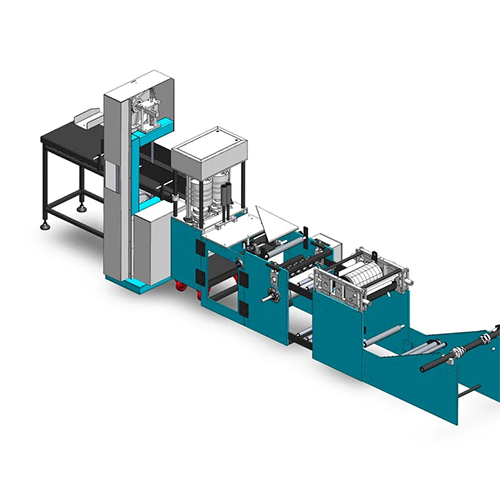

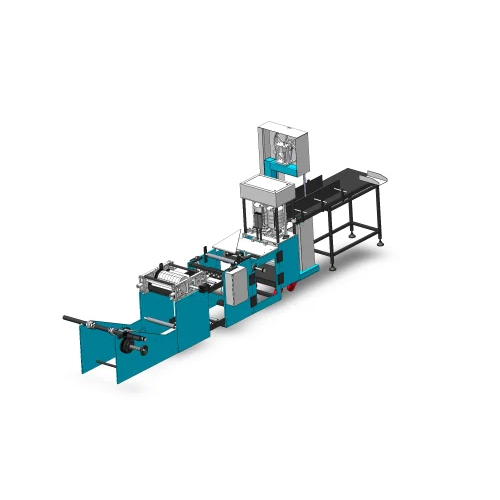

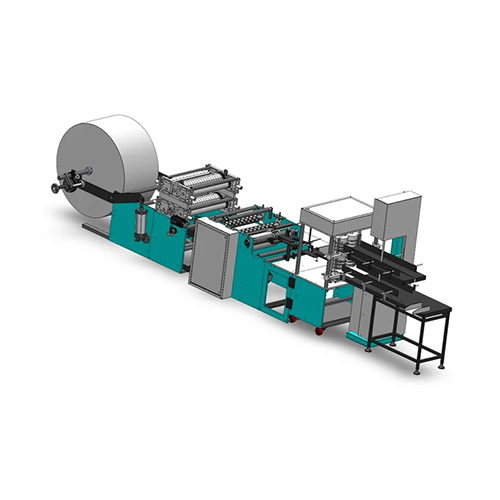

Automatic Tissue Paper Making Machine

Price 480000.00 INR/ Unit

Automatic Tissue Paper Making Machine Specification

- Grade

- Automatic

- Type

- Paper Cutting Machine

- Material

- MS, SS

- Computerized

- No

- Control System

- Frequency Speed Control

- Cutting Speed

- 375 m/m

- Cutting Size

- as per client requirement

- Voltage

- 440 Volt (v)

- Power

- 4 Horsepower (HP)

- Weight (kg)

- 1500 Kilograms (kg)

- Dimension (L*W*H)

- 4000 x 2000 x 1600 Inch (in)

- Color

- White & Orange & Blue

- Warranty

- 1 year

Automatic Tissue Paper Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Packaging Details

- Standard Practic

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, Africa, South America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

- Certifications

- ISO

About Automatic Tissue Paper Making Machine

With thorough understanding of the relevant industry, we are engaged in offering a unique range of Automatic Tissue Paper Making Machine that is used for making tissue paper. Offered tissue paper making machine is generally preferred for its low electricity consumption, space efficiency, high production rate and overlay accuracy. This machine can make tissue paper of different dimensions, shapes, colors, patterns and designs.Automatic Tissue Paper Making Machine has capacity of making 1800 packet of 15 GSM to 18 GSM paper thickness.

Advanced Construction for Lasting Performance

Engineered from both mild steel (MS) and stainless steel (SS), this machine is built for durability and efficiency in high-demand environments. The sturdy frame ensures stable operation, while the protective white, orange, and blue color finish provides a professional look and resistance to wear. Its robust construction stands up to continuous usage, reducing maintenance and downtime.

Automatic Functionality and User Flexibility

With an entirely automatic operation, this tissue paper machine simplifies handling for operators. The frequency speed control system provides precise speed adjustments, ensuring optimal cutting quality no matter the production volume. Cutting sizes can be customized as per client needs, making it versatile for different types of tissue paper products and requirements.

FAQs of Automatic Tissue Paper Making Machine:

Q: How does the automatic tissue paper making machine operate?

A: The machine uses an automatic paper cutting system controlled by a frequency speed control unit. Operators can set parameters based on tissue size requirements, and the machine adjusts speed and operation accordingly, providing seamless and efficient production without manual intervention.Q: What materials are used in the manufacturing of this tissue paper machine?

A: This machine is constructed using high-quality mild steel (MS) and stainless steel (SS), offering both strength and resistance to corrosion for extended service life in industrial settings.Q: When is routine maintenance recommended for this machine?

A: It is advisable to conduct regular maintenance checks after every operational cycle, or at least monthly, to ensure all moving parts are functioning optimally and to prevent unexpected downtime.Q: Where can this machine be installed and operated?

A: The machine is suitable for installation in industrial and commercial facilities such as tissue paper manufacturing units and factories, and requires adequate floor space given its dimensions of 4000 x 2000 x 1600 inches.Q: What is the process of setting the cutting size as per client requirements?

A: The operator can easily set or adjust the cutting size using the machines adjustable features before starting a production run to meet specific client demands for tissue dimensions.Q: How is the power supply managed for the tissue paper machine?

A: This machine operates on a 4 HP motor with a power requirement of 440 volts. It should be connected to an industrial electrical supply fitting these specifications for optimal performance.Q: What are the key benefits of using this automatic tissue paper machine?

A: With its robust build, reliable automatic operation, customizable cutting sizes, and efficient speed control, the machine offers increased productivity, reduced labor, lower maintenance needs, and consistently high-quality tissue output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tissue Paper Making Machine Category

440V Automatic Tissue Paper Making Machine

Price 800000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Control System : PLC Control

Grade : Automatic

Material : MS

Paper Napkin Making Machine

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : PLC Control

Grade : Automatic

Material : MS

3 Phase Tissue Paper Making Machine

Price 450000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Control System : PLC Control

Grade : Automatic

Material : MS

Computerized Tissue Paper Making Machine

Price 820000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Yes

Control System : PLC Control

Grade : Automatic

Material : SS

GST : 24CNQPP5534B1ZY

|

|

RAJSHREE INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry