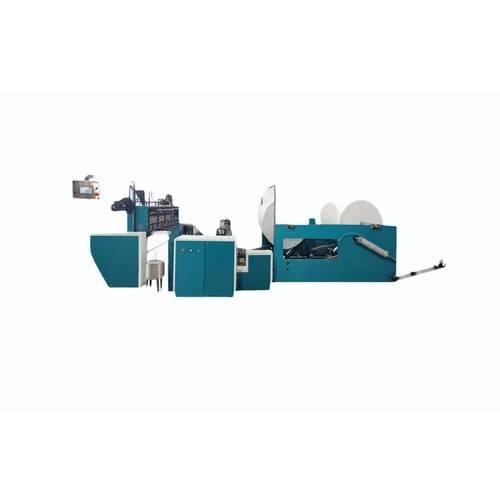

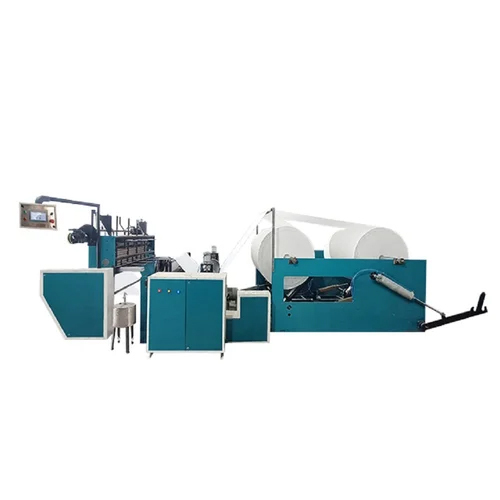

Industrial Toilet Roll Making Machine

Price 500000.00 INR/ Unit

Industrial Toilet Roll Making Machine Specification

- Grade

- Automatic

- Type

- Paper Cutting Machine

- Material

- MS, SS

- Capacity

- 50 roll Pcs/min

- Computerized

- Yes

- Control System

- PLC Control

- Cutting Speed

- 40-100 roll/min mm/m

- Cutting Size

- 100 mm

- Voltage

- 440 Volt (v)

- Power

- 10 Watt (w)

- Weight (kg)

- 2.5 Metric Ton

- Dimension (L*W*H)

- 8000 x 2000 x 1600 Millimeter (mm)

- Color

- Blue & White

- Warranty

- 1 year

Industrial Toilet Roll Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 45 Days

- Packaging Details

- Standard Practice

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO Certification

About Industrial Toilet Roll Making Machine

With an aim of being best in market, we are capable to offer wide assortment of Toilet Roll Making Machine. Our machine is used for producing toilet paper in various country. It is made under proper supervision of our adroit professionals in order to deliver flawless machines to our clients. Further, Toilet Roll Making Machine is manufactured using sophisticated technology to transmit it exclusive features. It has excelled in market since years because of its brilliant functionality and durability. Also, it is available in different models and technical specifications keeping in mind various needs of customers.

Advanced Cutting Precision

Featuring a computerized PLC control system, this machine provides consistent and accurate cutting at a standard size of 100 mm. Its automated process ensures uniformity in roll size, minimizing waste and optimizing output for high-demand industrial operations.

Robust Material and Construction

Manufactured using high-quality mild steel (MS) and stainless steel (SS), the machine promises remarkable durability and longevity. Its heavy-duty construction, weighing 2.5 metric tons, guarantees stability during high-speed operations, making it suitable for continuous use in industrial settings.

High Production Capacity

Capable of handling up to 50 rolls per minute with speeds between 40 and 100 rolls, this machine significantly enhances manufacturing efficiency. Its large working area (8000 x 2000 x 1600 mm) accommodates high-volume production without compromising on precision or performance.

FAQs of Industrial Toilet Roll Making Machine:

Q: How does the machine ensure accurate and consistent cutting of toilet rolls?

A: The machine utilizes PLC-controlled automated cutting mechanisms that maintain precise measurements at 100 mm per roll. This computerized system minimizes errors, delivering consistently sized rolls every time.Q: What is the typical process for operating this toilet roll making machine?

A: Operation involves loading raw paper material, setting desired cutting parameters via the PLC interface, and initiating the automated process. The machine then feeds, cuts, and outputs finished rolls accurately at high speed with minimal manual intervention.Q: When is it advisable to perform maintenance on the machine?

A: Regular maintenance checks should be conducted as per the manufacturers guidelines, typically after every extended production run or monthly. Lubrication, clearing of debris, and inspection of moving parts ensure longevity and optimal performance.Q: Where can this industrial toilet roll making machine be best utilized?

A: This equipment is ideal for use in large-scale manufacturing plants, distribution centers, or facilities specializing in hygiene product production across India, given its high capacity and robust design.Q: What benefits does the automatic grade and PLC control system offer?

A: The full automation and PLC control provide streamlined operations, reduce labor dependency, and enhance safety. This results in higher productivity, reduced error rates, and improved overall efficiency.Q: How does the choice of materials (MS, SS) affect machine durability?

A: Employing mild steel (MS) and stainless steel (SS) delivers excellent resistance to corrosion and mechanical wear, which is crucial for ensuring the machine withstands intensive, continuous operation in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Toilet Roll Making Machine Category

Automatic Toilet Band Saw Cutter

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Material : Paper

Voltage : 440 Volt (v)

Grade : Automatic

Mild Steel Fully Automatic Toilet Roll Making Machine

Price 650000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Material : Mild Steel

Voltage : 440 Volt (v)

Grade : Automatic

415V Toilet Paper Roll Making Machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Material : Mild Steel

Voltage : 415 Volt (v)

Grade : Automatic

Wet Wipe Tissue Roll (Cannister) Making Machine

Price 900000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Material : Fabric, Chemicals

Voltage : 440 Volt (v)

Grade : Automatic

GST : 24CNQPP5534B1ZY

|

|

RAJSHREE INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry