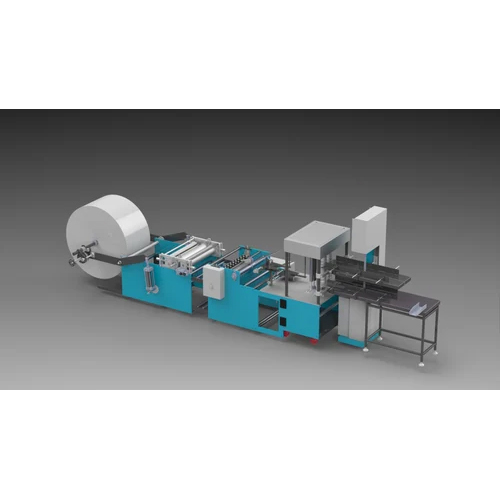

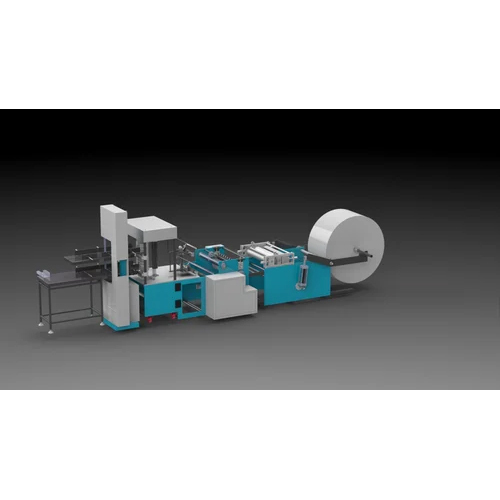

Electric Tissue Paper Making Machine

Price 450000.00 INR/ Unit

Electric Tissue Paper Making Machine Specification

- Grade

- Automatic

- Material

- MS, SS

- Capacity

- 400 Pcs/min

- Computerized

- No

- Control System

- Human Machine Interface

- Cutting Speed

- 400 m/m

- Cutting Size

- as per client requirement

- Cutting Thickness

- as per client requirement Centimeter (cm)

- Voltage

- 440 Volt (v)

- Power

- 4 Horsepower (HP)

- Weight (kg)

- 2000 Kilograms (kg)

- Dimension (L*W*H)

- 204 x 60 x 84 Inch (in)

- Color

- White & Orange & Blue

- Warranty

- 1 year

Electric Tissue Paper Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Packaging Details

- plastic wrapping

- Main Domestic Market

- All India

- Certifications

- ISO

About Electric Tissue Paper Making Machine

By utilizing skills of our dexterous workforce, we are offering a distinguished assortment of 3 HP Automatic Tissue Paper Making Machine. The given machine is best in terms of efficiency, energy consumption, production rate, durability etc. This machine is used for making toilet tissue paper, tissue facial paper etc. 3 HP Automatic Tissue Paper Making Machine performs different operations such as pneumatic cutting, folding, cutting, embossing etc. This tissue paper making machine is available in 220-410 V voltage 50 Hz frequency.

FAQs:

Q: What is a tissue paper making machine used for?

A: A tissue paper making machine is used to produce tissue paper products such as toilet paper, napkins, and paper towels.

Q: How does a tissue paper making machine work?

A: A tissue paper making machine works by processing pulp and water mixture into a mesh conveyor where it is pressed and dried to form tissue paper.

Q:What is the cost of a tissue paper making machine?

A:The cost of a tissue paper making machine can vary depending on the capacity and features, but it can range from a few thousand to hundreds of thousands of dollars.

Q: What type of materials can be used in a tissue paper making machine?

A: A tissue paper making machine can use recycled paper or virgin pulp as raw material.

High Efficiency and Customization

Designed for maximum productivity, this machine cuts tissue paper at an impressive speed of 400 meters per minute, yielding up to 400 pieces per minute. Clients can request specific cutting sizes and thicknesses to tailor the output to their business needs, making it ideal for a wide range of applications.

Intuitive Operation and Control

The advanced Human Machine Interface ensures that operators can monitor and control every stage of tissue paper production with ease. Despite being a fully automatic machine, it is user-friendly and requires minimal manual intervention, enhancing operational efficiency and safety.

Durable Construction and Reliable Performance

Manufactured using top-grade mild steel (MS) and stainless steel (SS), this tissue paper making machine is engineered to withstand rigorous industrial environments. Its sturdy construction ensures long lifespan and consistent output, supported by a one-year warranty for additional peace of mind.

FAQs of Electric Tissue Paper Making Machine:

Q: How is the cutting size and thickness of tissue paper customized with this machine?

A: The Electric Tissue Paper Making Machine allows clients to specify both the cutting size and thickness during the ordering process. These settings are incorporated into the machines configuration, enabling precise adjustments in production to meet unique requirements.Q: What control system does the machine utilize, and how does it benefit operators?

A: The machine is equipped with a Human Machine Interface (HMI) control system, which provides a straightforward interface. This system simplifies operation, allows for efficient monitoring, and ensures seamless customization of production parameters, reducing the likelihood of error.Q: When should routine maintenance be performed to ensure optimal performance?

A: Routine maintenance is advised at regular intervals, depending on usage intensity. Basic cleaning and inspection should occur weekly, while comprehensive checks and lubrication are recommended monthly to uphold efficiency and minimize downtime.Q: Where is this tissue paper making machine suitable for installation?

A: Due to its industrial-grade construction and large dimensions (204 x 60 x 84 inches), the machine is best installed in spacious factory environments or manufacturing plants. Adequate space and appropriate electrical arrangements (440V) should be ensured at the site.Q: What is the process for operating this automatic tissue paper making machine?

A: Operation is straightforward: Load the appropriate paper roll as input, set the desired cutting size and thickness on the control interface, and start the machine. The automated system handles feeding, cutting, and stacking, delivering up to 400 pieces per minute.Q: What are the key benefits of using this tissue paper making machine for businesses?

A: This machine offers high-speed, high-capacity automated production, minimized manual intervention, and the ability to tailor output. Its robust construction and one-year warranty ensure reliability, while advanced controls maximize productivity and consistency for businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tissue Paper Making Machine Category

Printed Tissue Paper Making Machine

Price 820000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Control System : PLC Control

Warranty : 1 Year

Grade : Automatic

Three Phase Tissue Paper Making Machine

Price 900000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue

Control System : PLC Control

Warranty : 1 Year

Grade : Automatic

Electric Tissue Paper Making Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Control System : PLC Control

Warranty : 1 Year

Grade : Automatic

Fully Automatic Tissue Paper Making Machine

Price 1100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue

Control System : PLC Control

Warranty : 1 Year

Grade : Automatic

GST : 24CNQPP5534B1ZY

|

|

RAJSHREE INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry